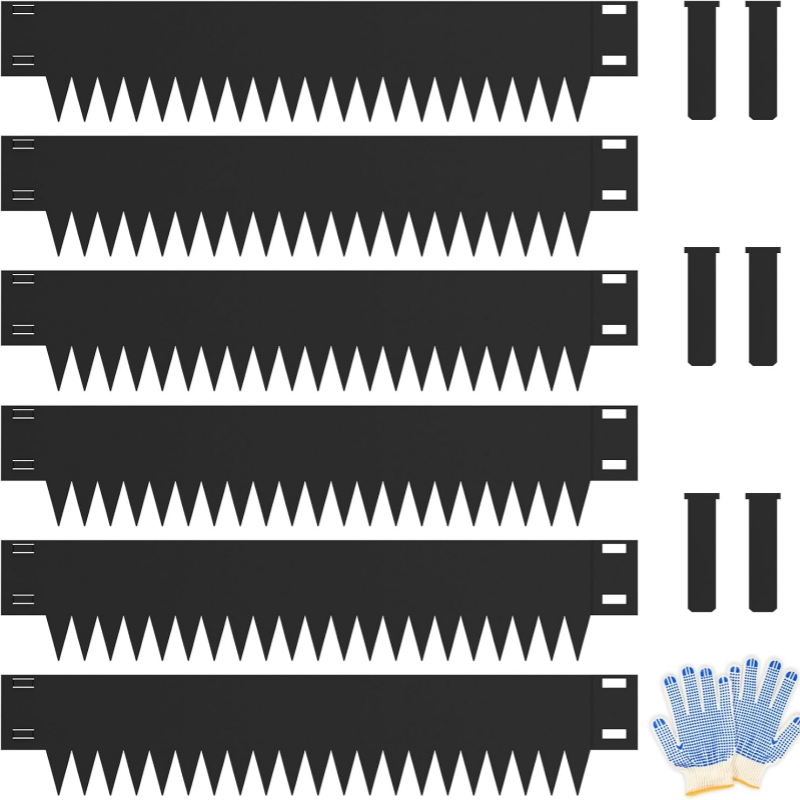

Custom Metal Landscape Edging

Custom metal landscape edging offers a perfect blend of functionality, durability, and aesthetic appeal, making it an ideal choice for modern landscape design. One of its primary advantages is the ability to meet personalized requirements. Whether it’s specific dimensions, unique shapes, or intricate patterns, custom designs ensure the edging complements any garden or landscape style. High-quality materials, such as aluminum, galvanized steel, or stainless steel, are often used, providing excellent durability, weather resistance, and long service life. Customization also allows seamless adaptation to various applications, from residential gardens to commercial spaces, ensuring harmony with the surrounding environment. Additionally, incorporating logos, patterns, or unique elements into the design can reflect personal style or enhance brand identity, making it a versatile option for both private and business customers. Custom edging often uses eco-friendly, recyclable materials, aligning with sustainability goals. Moreover, professional design and support services ensure the final product is both functional and visually striking, adding value to any outdoor space.

Custom Metal Landscape Edging Process

Initial Consultation and Requirements Gathering

The process begins with a detailed consultation where clients share their specific needs, including dimensions, shapes, materials, colors, and design preferences. Supporting materials such as sketches, photos, or landscape plans can be provided for better alignment with the project requirements.

Design and Concept Development

Based on the client’s input, the design team creates detailed concepts using CAD or similar software. These designs include accurate dimensions and visual representations. Clients review the designs and provide feedback, ensuring the final concept matches their expectations.

Material Selection

Suitable materials are selected based on the project’s functional and aesthetic needs. Common options include aluminum, galvanized steel, stainless steel, or corten steel, chosen for their durability, weather resistance, and visual appeal.

Prototyping (Sample Creation)

A prototype or sample of the custom metal landscape edging is produced to validate the design and material choice. This allows clients to assess the product's quality, finish, and functionality before proceeding to full production.

Revisions and Final Approval

If necessary, adjustments are made based on feedback from the prototype. Once the design and sample are approved, the project moves to the manufacturing phase.

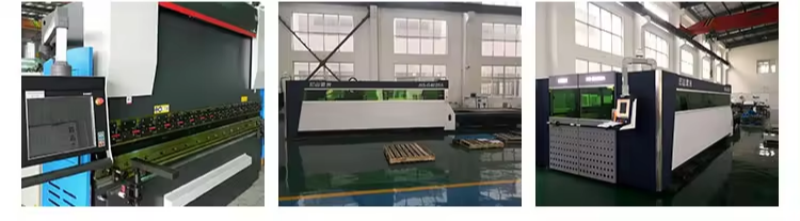

Manufacturing

The approved design is sent to production, where advanced manufacturing techniques such as laser cutting, welding, and precision forming are used to create the custom edging. Strict quality controls are maintained during production to ensure consistency and durability.

Finishing and Surface Treatment

After manufacturing, the edging undergoes finishing processes, including smoothing edges and applying surface treatments such as powder coating, anodizing, or painting. These treatments enhance the product's durability, weather resistance, and appearance.

Quality Inspection

Each piece undergoes a thorough quality inspection to ensure it meets the approved design and specifications. This includes verifying dimensions, surface finishes, and overall structural integrity.

Packaging and Delivery

The completed products are securely packaged to prevent damage during transportation. Delivery is arranged according to the client’s schedule and location, ensuring the edging arrives in perfect condition.